In the drilling industry, oilfield elevators are the unsung heroes that keep operations moving smoothly. These essential hoisting tools lift and lower drill pipe, casing, drill collars, and tubing with precision. But to truly maximize efficiency and safety, elevators need more than just robust construction—they need the support of beckets and bails. In this blog, we’ll explore how these additional tools contribute to the overall rigging process and help prevent downtime.

- Elevators in the Drilling Process

- The Role of Beckets and Bails in the Rigging Process

- Enhancing Safety with Beckets and Bails

- Keystone's Beckets and Bails: Engineered for Efficiency

Elevators in the Drilling Process

Oilfield elevators are designed to securely handle tubulars throughout drilling operations. Whether you’re working with shoulder drill pipe, casing, or tubing, elevators ensure that these critical components are safely hoisted and lowered. Without reliable elevators, even minor issues can halt drilling operations and lead to costly delays. Remember that when your elevator performs optimally, it directly influences the efficiency of the entire drilling process.

The Role of Beckets and Bails in the Rigging Process

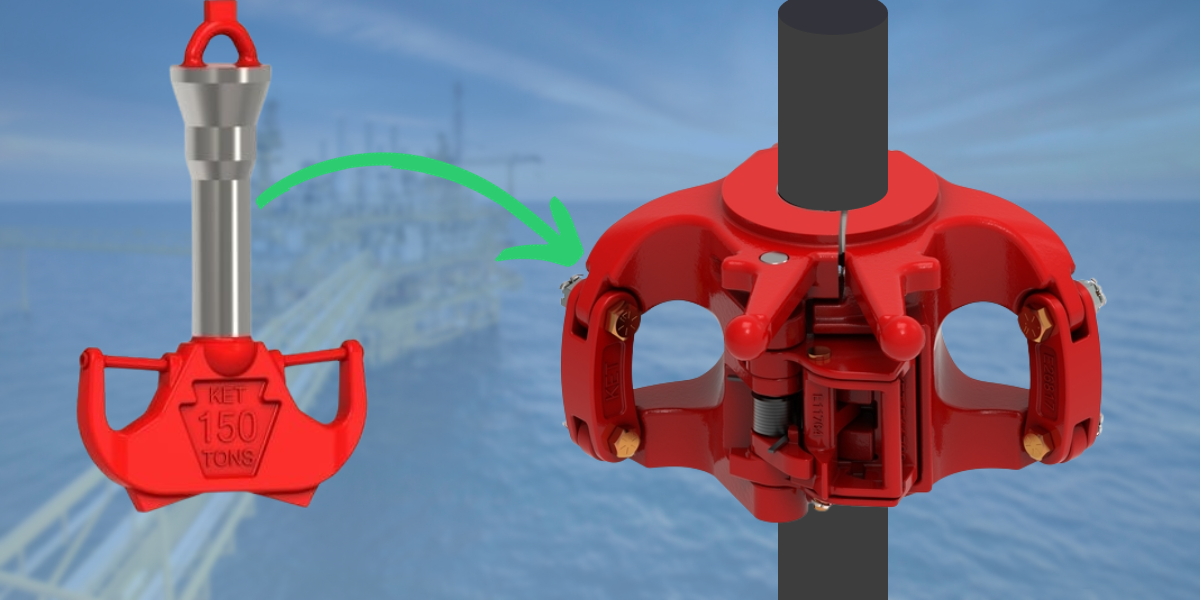

Beckets and bails serve a very specific, yet crucial, purpose in drilling rig operations. A becket is an inverted U-shaped bar that attaches to the main elevator at the top. It works in tandem with a set of bails (also known as perfection links) attached at the bottom. Together, they support a secondary elevator that can run short strings of tubulars or connections different from those handled by the main elevator.

This dual setup saves significant time and effort. Instead of rigging down the main elevator to switch tubular sizes, operators can simply utilize the secondary elevator provided by the beckets and bails. This streamlined process not only boosts efficiency but also reduces the risk of errors and potential downtime.

Enhancing Safety with Beckets and Bails

Safety is paramount in every drilling operation, and proper rigging is a key element of maintaining a secure work environment. By ensuring that tubulars are consistently aligned and securely connected, beckets and bails play a critical role in preventing misalignment and damage. Here are a few essential safety tips when using these tools:

- Routine Inspections: Always inspect the elevator, beckets, and bails before each use to check for any signs of wear or damage.

- Positive Latching: Elevators should be equipped with safety or positive latches to avoid accidental disengagement during operation.

- Clear Rigging Paths: Ensure that all rigging equipment is free from projections that might catch on other components, reducing the risk of accidents.

Keystone's Beckets and Bails: Engineered for Efficiency

At Keystone Energy Tools, we understand that every minute counts on the rig. That’s why we offer two types of beckets to meet your operational needs. Our standard beckets work seamlessly with standard drill pipe elevators, while our extended shank beckets are specifically designed for tall, hydraulic elevators. Additionally, we produce three lengths of bails—available in 36, 42, and 60 inches, with load capacities of 100 and 150 tons—to ensure you have the right fit for any job.

These high-quality beckets and bails not only enhance the rigging process but also help prevent damage to your tubulars, ensuring that every connection is made with precision. With Keystone’s engineered solutions, you save time and money by eliminating the need to change the main hoisting elevator when running different tubular sizes.

A Commitment to Excellence in Drilling Operations

Incorporating beckets and bails into your rigging process is more than just an upgrade—it’s an investment in safety, efficiency, and long-term operational success. At Keystone Energy Tools, our products are built with the highest quality materials and precision machining to meet and exceed industry standards. With our comprehensive range of oilfield tools, including elevators, beckets, and bails, you’re equipped to handle even the most demanding drilling applications.

By choosing Keystone, you’re not only enhancing your current rigging process but also setting the stage for a safer, more productive future in oil and gas drilling. Explore our product line today and see how our innovative solutions can keep your operations running at peak performance.

About Keystone Energy Tools

Keystone Energy Tools is a manufacturer with over fifty years of combined experience in designing, manufacturing, and delivering high-quality oilfield tools, including elevators, slips, dies and inserts, tongs dies, safety clamps, stabbing guides, drill pipe float valves, baffle plates, float valve pullers, rotating mouseholes, and tong blocks.

Keystone Energy Tools is a manufacturer with over fifty years of combined experience in designing, manufacturing, and delivering high-quality oilfield tools, including elevators, slips, dies and inserts, tongs dies, safety clamps, stabbing guides, drill pipe float valves, baffle plates, float valve pullers, rotating mouseholes, and tong blocks.

By using the latest in 3D modeling for product design and by staying current with the rapid advances in manufacturing technology and quality-assurance standards, Keystone is able to manufacture and produce the most reliable products on the market today. All Keystone Handling Tools are manufactured according to API 8C and API 7K Standards.