%20(1).png?width=870&height=435&name=Untitled%20design%20(15)%20(1).png)

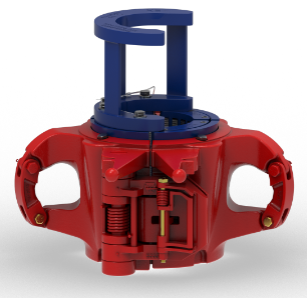

Keystone offers Y Series Slip Type Elevators. The Y Series Elevators are center latch, tubing elevators made to catch collar type or integral joint tubing, and casing.

Slip-type elevators hold and hoist tubing and casing for completion and production operations. They are especially suitable for the hoisting of integral joint tubing and casing.

The models used for tubing are the LYT, MYT, YT, and HYT; and the YC, MYC, HYC, HYC-CL, and HYC-CC for casing.

All slip backs and die slots on Keystone slips are precision machined to ensure proper grip and to prevent bottlenecking or slip cuts to the pipe. All Keystone slip type elevators are manufactured in the United States and built to meet or exceed API 8C standards.

Our slips and elevators come with a complete data book, including material and heat certification. This certification ensures your equipment is manufactured with steel from trusted vendors. The KET and API stamp indicate a seal of quality.

- LYT (20 Ton)

- MYT (40 Ton)

- YT (75 Ton)

- HYT (150 Ton)

- HYT-SS (150 Ton)

- HYC (200 Ton)

- HYC- XR (200 Ton)

- HYC-CL (200 Ton)

- HYC-CL-XR (250 Ton)

- HYC-CC-XR (300 Ton)

- HYC-CCL-XR (350 Ton)

- MYC (125 Ton)

- YC (75 Ton)

- Safety Concerns with Rig Floor Equipment

1- LYT Slip Type Elevator

Keystone Energy Tools LYT slip type elevators are designed to be used on all API collar type or integral joint tubing. They are well-balanced making them easy to handle and latch on/off the tubular. The slip mechanism incorporates four interlocking slips ensuring a uniform grip with minimum marking of the tubular.

The LYT 20 Ton Slip Type Elevator is designed to handle small size tubing. The LYT size range is 3/4” through 2-1/16” and requires only one size slip to handle its full range. Rated capacity is 20 tons.

2- MYT Slip Type Elevator

The MYT slip type elevator are also designed to be used on all API collar type or integral joint tubing. They are well balanced making them easy to handle and latch on/off the tubular. The slip mechanism incorporates four

interlocking slips ensuring a uniform grip with minimum marking of the tubular.

The MYT 40 Ton Slip Type Elevator is a lightweight tubing elevator used for holding and hoisting oilfield tubing. The MYT size range is 3/4” through 2-7/8” and requires only one size slip to handle its full range. Rated capacity is 40 tons.

3- YT Slip Type Elevator

Just like the LYT and MYT, the YT Slip Type Elevators are also designed to be used on all API collar type or integral joint tubing. They are well balanced making them easy to handle and latch on/off the tubular. The slip mechanism incorporates four interlocking slips ensuring a uniform grip with minimum marking of the tubular.

A medium weight tubing elevator for tubing 1.315″ through 3 1/2″, the YT requires the use of two sizes of slips to handle its full range. Rated capacity is 75 tons.

4- HYT Slip Type Elevator

The Keystone Energy Tools HYT Slip Type Elevators are designed to be used on all API collar type or integral joint tubing. They are well balanced making them easy to handle and latch on/off the tubular. The slip mechanism incorporates four interlocking slips ensuring a uniform grip with minimum marking of the tubular.

A heavyweight tubing elevator, the HYT is for tubing 2 3/8″ through 3 ½” and only requires one size slip to handle its full range. Rated capacity is 150 tons.

5- HYT-SS Slip Type Elevator

Keystone Energy Tools HYT-SS Slip Type Elevators are designed suitable for use running flush, near flush, slim hole (PAC) tubulars. They are well balanced making them easy to handle and latch on/off the tubular. All HSS’s incorporate a hydraulic cylinder mounted on the guide plate that controls the slips from setting up and down. The slip gripping mechanism is set hydraulically with controls by the driller.

A heavyweight tubing elevator, the HYT-SS is for tubing 2 3/8″ through 3 1/2″. It requires the use of one slip to handle its full range. Rated capacity is 150 tons.

6- HYC Slip Type Elevator

The HYC Slip Type Elevators are designed to be used on all API collar type or integral joint casing. They are well balanced making them easy to handle and latch on/off the tubular. The slip mechanism incorporates four interlocking slips ensuring a uniform grip with minimum marking of the tubular.

A heavyweight casing elevator, the HYC is for tubing 3 1/2" through 7 5/8". It requires the use of three sizes of slips to handle its full range. Rated capacity is 200 tons.

7- HYC-XR Slip Type Elevator

Keystone Energy Tools HYC-XR Slip Type Elevators are designed to be used on all API collar type or integral joint casing. They are well balanced making them easy to handle and latch on/off the tubular. The slip mechanism incorporates four interlocking slips ensuring a uniform grip with minimum marking of the tubular.

A heavyweight casing elevator, the HYC is for casing 7 5/8" through 9 5/8". It requires the use of one size of slips to handle its full range. Rated capacity is 200 tons.

8- HYC-CL Slip Type Elevator

Keystone Energy Tools HYC-CL Slip Type Elevators are designed to be used on all API collar type or integral joint casing. They are well balanced making them easy to handle and latch on/off the tubular. The slip mechanism incorporates four interlocking slips ensuring a uniform grip with minimum marking of the tubular.

Rated for a capacity of 250 tons, the HYC-CL offers reliable performance for even the most demanding casing applications ranging from 3 1/2” through 7 5/8”.

9- HYC-CL-XR Slip Type Elevator

Keystone Energy Tools HYC-CL-XR 250 Ton Slip Type Elevator is engineered for precision and reliability in casing operations. Designed specifically for casing applications, it accommodates tubulars with diameters from 7 5/8” to 9 5/8”. With its robust construction and advanced slip mechanism, this elevator ensures balanced handling, efficient latching, and a uniform grip that minimizes marking.

Rated for a capacity of 250 tons, the HYC-CL-XR delivers dependable performance even in the most demanding environments.

10- HYC-CC-XR Slip Type Elevator

Keystone Energy Tools HYC-CC-XR 300 Ton Slip Type Elevator is built for heavy-duty performance in casing operations. It is designed to handle tubulars with diameters ranging from 8 5/8” to 10 3/4”, and its robust engineering supports a rated capacity of 300 tons.

The elevator features a secure latching system and a well-balanced design, ensuring efficient handling and minimal marking on the tubulars. This makes the HYC-CC-XR an ideal solution for demanding casing applications.

11- HYC-CCL-XR Slip Type Elevator

Keystone Energy Tools HYC-CC-XR 350 Ton Slip Type Elevator sets the standard for durability in heavy-duty casing operations. It accommodates pipe diameters from 8 5/8” to 10 3/4” while managing up to 350 tons of load. Featuring an advanced design for balanced handling and a secure, efficient latching system, this elevator minimizes marking and optimizes connection integrity.

Engineered to perform under the most challenging conditions, the HYC-CC-XR 350 Ton Elevator is a reliable choice for high-demand casing applications.

12- MYC Slip Type Elevator

The MYC Slip Type Elevators are also designed to be used on all API collar type or integral joint casing. They are well balanced making them easy to handle and latch on/off the tubular. The slip mechanism incorporates four interlocking slips ensuring a uniform grip with minimum marking of the tubular.

A casing elevator, the MYC is for tubing 3 1/2" through 7". It requires the use of two three of slips to handle its full range. Rated capacity is 200 tons.

13- YC Slip Type Elevator

Keystone Energy Tools YC Slip Type Elevators are designed to be used on all API collar type or integral joint casing. They are well balanced making them easy to handle and latch on/off the tubular. The slip mechanism incorporates four interlocking slips ensuring a uniform grip with minimum marking of the tubular.

A medium weight tubing elevator, the YC is for tubing 3 1/2" through 7". It requires the use of three sizes of slips to handle its full range. Rated capacity is 75 tons.

Keystone also carries slip-type elevator parts, including rings, hinge pins, latch pins, cotter pins, latch locks, and slip bolts.

Safety Concerns with Rig Floor Equipment

When drilling operations call for the use of slip-type elevators, the following precautions should be taken:

-

Slip-type elevators must close completely, and the latch must engage properly. Double-check the elevator body, latch mechanism, links, and dies and setting plate. Keep hands away from any pinch point or undesignated areas; use only the provided handles for operating the elevator.

-

Elevators should be cleaned frequently to reduce the risk of slippage, and to ensure that they are working properly. If slips are used, make sure the dies are clean and sharp, and all the same size. Do not mix old or resharpened dies with new dies in the elevator slips.

-

Blocks should be completely stopped prior to latching the elevators on the pipe. The blocks must be raised slowly to allow the elevators to slide up to the pipe upset area. Check that the blocks are centered over the rotary table. Any misalignment can result in difficulty when stabbing and spinning up connections.

-

Pipe should be stood back in the derrick no further than necessary, eliminating as much “bowing” as possible. Personnel responsible for “tailing” the pipe should keep the pipe at arm’s length at all times.

-

Workers should never position themselves directly understands or joints of the drilling string. Use a tail rope that allows employees to stand well away from the pipe at initial pick-up.

Learn more about our slip type elevators

View all sizes, load rating, and parts.

Equipment repair by Keystone Energy

We specialize in giving life back to your equipment and tools, regardless of age, size, or condition.

All equipment is brought into one of our shops and completely disassembled and thoroughly inspected to enable us to get you back up and running.

Our technicians are able to build your component back to OEM specifications as well as recertify most equipment.

Related Articles

Top 10 Trends Shaping the Oil and Gas Industry - Let's explore 10 of these trends that are transforming the outlook of the oil and gas industry for 2021 and beyond.

The importance of equipment repairs and maintenance in the oil and gas industry - Repair and maintenance are essential to mitigate corrosion, increase safety, and reduce expenses long term.

What are the challenges that Slim Hole Drill Pipe has on elevators? - Slim Hole drill pipe creates some unique challenges for the lifting capacity on Elevators. Let’s dive into the details.

About Keystone Energy Tools

Keystone Energy Tools is a manufacturer with over fifty years of combined experience in designing, manufacturing, and delivering high-quality oilfield tools, including elevators, slips, dies and inserts, tongs dies, safety clamps, stabbing guides, drill pipe float valves, baffle plates, float valve pullers, rotating mouseholes, and tong blocks.

Keystone Energy Tools is a manufacturer with over fifty years of combined experience in designing, manufacturing, and delivering high-quality oilfield tools, including elevators, slips, dies and inserts, tongs dies, safety clamps, stabbing guides, drill pipe float valves, baffle plates, float valve pullers, rotating mouseholes, and tong blocks.

By using the latest in 3D modeling for product design and by staying current with the rapid advances in manufacturing technology and quality-assurance standards, Keystone is able to manufacture and produce the most reliable products on the market today. All Keystone Handling Tools are manufactured according to API 8C and API 7K Standards.