.jpg?width=870&height=435&name=Facebook%20-%20Featured%20Image%20-%20Keystone%20(2).jpg)

What are the challenges that Slim Hole Drill Pipe has on elevators? Are you considering which style elevator is the best for the application?

In this blog we will evaluate these challenges. Also, let’s dive into the details that separate the IB (Insert Bushing) Type Elevators from Traditional Bottleneck Elevators when running Slim Hole Drill Pipe.

- What are the Elevator Bore Ratings?

- What effects the lifting capacity and ratings on Slim Hole drill pipe elevators?

- Where does a drill pipe elevator wear?

- What causes a drill pipe elevator wear?

- What is the cost difference in repairing traditional bottleneck elevators vs IB elevators

- FEA Analysis Results

What are the Elevator Bore Ratings?

The Chart below shows the calculated bore rating for traditional elevators compared to IB Type Elevators when used on standard API connections and common slim-hole connections. The bore ratings are calculated by determining the total contact area of the elevator taper and the tool jt. taper.

|

Pipe OD |

Connection |

Min. TJ |

Bore Rating |

Bore Rating |

Thru Bore |

Contact |

Contact |

|

Size |

Type |

OD |

Traditional / Tons |

IB Type / Tons |

New |

Area Total |

Per side |

|

4" |

FH |

5.138 |

389 |

495 |

4.281 |

0.857 |

0.429 |

|

4" |

XT-39 |

4.68 |

197 |

250 |

4.22 |

0.460 |

0.230 |

|

4 1/2" |

NC46 |

5.625 |

423 |

538 |

4.781 |

0.844 |

0.422 |

|

4 1/2" |

XT-43 |

5.156 |

203 |

258 |

4.73 |

0.426 |

0.213 |

|

5" |

NC50 |

5.875 |

335 |

426 |

5.25 |

0.625 |

0.313 |

|

5" |

Delta 474 |

5.741 |

275 |

350 |

5.22 |

0.521 |

0.261 |

|

5 1/2" |

FH |

6.5 |

407 |

518 |

5.813 |

0.687 |

0.344 |

|

5 1/2" |

Delta 544 |

6.232 |

289 |

368 |

5.73 |

0.502 |

0.251 |

The increased rating of the IB elevator is achieved by the higher yield strength material of the insert bushing that the tool jt. contacts with.

Also shown in the chart is the IB elevator has an approximate 27% heavier bore rating when compared to a traditional elevator. Slim-Hole tool joints compared to standard API tool joints can impact the bore rating of the elevator by 25 to 100%.

Using an elevator at the maximum rated capacity increases the stress and therefore accelerates the wear to the elevator.

With the IB elevator the bushing transfers the load of the pipe over the complete taper of the elevator. This virtually eliminates the need to weld repair the elevator bore in the future.

What effects the lifting capacity and ratings on Slim Hole drill pipe elevators?

1- Tool Joint diameters on drill pipe

Slim Hole drill pipe tool joints ODs are smaller and provide less contact area than standard API drill pipe tool joints.

2- The diameter of the thru-bore on the elevator

The bore diameters on traditional elevators and insert bushings are specific for each tool jt. and connection size. As the bore wears and the diameter becomes greater, the stress increases and the rated capacity decreases. The traditional elevator bore will wear at a much higher rate compared to the insert bushing. Continue reading to find out why.

3- Yield strength of the material used (Material characteristics)

The elevator bodies can be described as complex shapes. Because of these complex shapes, elevators are made with low alloy high strength heat treated steel castings.

This type of material is used to meet the physical characteristics and impact values, which has a lower hardness than what can be achieved in other high alloy heat treated materials. The insert bushing is made of a high alloy modified steel that provides a much higher yield, tensile, and hardness results.

4- Contact area

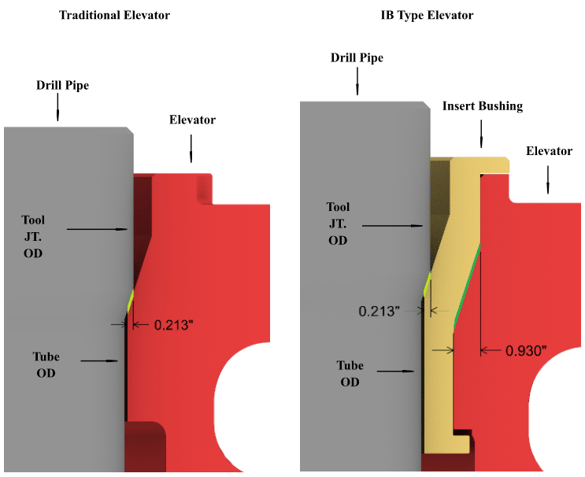

Traditional elevators have a minimal amount of contact with the drill pipe. That is where the TJ taper contacts with the taper of the elevator bore. Whereas with IB Type Elevators provides two methods of contact.

One is where the TJ taper contacts the taper of the insert bushing taper and the second is the full contact of the insert bushing external taper and the taper of the elevator bore. The below illustration shows the contact areas on both style elevators when running 4 ½” SH XT-43 Drill Pipe.

Where does a drill pipe elevator wear?

Elevators wear in 4 different ways but only 3 are increased when running Slim-Hole drill pipe.

1- The bore will wear on conventional elevators and the insert bushing on IB elevators

Traditional bottleneck elevators manufactured for use with slim hole drill pipe regularly require weld repairs to the bore.

The bores of an IB bottleneck elevator rarely require the need for weld repair. The insert bushing will wear but at a much slower rate. When the bushing is worn it can be replaced in the field without the need to send it in to a repair facility.

The traditional elevator bore will wear quicker than the insert bushings bore because it’s made from a low alloy steel casting and the bushing is made from high alloy steel with increased tensile/yield properties.

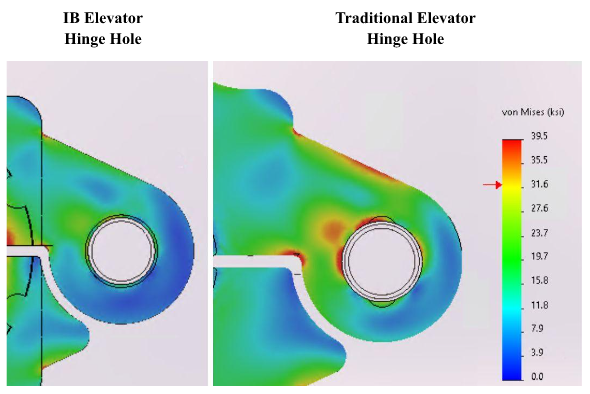

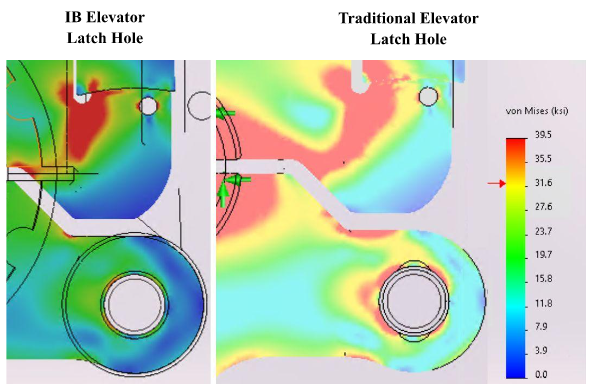

2- The hinge and latch pins

When bottleneck elevators are under a working load, there is a spreading force applied to the elevator because the drill pipe and the elevator's contact area is an 18-degree taper. This creates wear on the pins in the areas they contact the body, door, and/or latch. An FEA analysis conducted provides evidence supporting this data learned from historical performance that increased stress creates increased wear.

See FEA below.

3- The hinge and latch pins holes

These two holes also wear for the same reasons above. The holes can be reamed to a bigger size requiring an oversized pin, but once the maximum hole size is reached, the holes must be weld repaired back to nominal sizes to be within spec. An FEA analysis conducted provides evidence supporting this data learned from historical performance.

4- The ears

The ears of the elevator are also a wear factor that is taken into consideration when determining if an elevator is acceptable for use or not. The ears are normally worn by the elevator rotating in the bails but has no correlation to wear received from operating Slim-Hole drill pipe.

What causes a drill pipe elevator wear?

There are several reasons that cause a drill pipe elevator to wear.

The amount of load/stress on the elevator

There is a direct correlation with applied load/stress and component wear. The higher the stress in an elevator directly increases the amount of wear and the rate at which the elevator wears on.

The amount of contact the tool joint taper has on the 18-degree taper/bore

Slim Hole drill pipe have smaller tool joints than standard API drill pipe. Tool Joints also see wear which reduces the diameter of its TJOD and taper contact area.

Keeping the elevator latched around the pipe during drilling operations

This causes the bore in the elevator to wear unsymmetrical reducing the contact area which consequently increases the applied stress to the elevator.

What is the cost difference in repairing traditional bottleneck elevators vs IB elevators

On average, it cost around 40% more to repair and recertify a traditional bottleneck elevator versus an IB bottleneck elevator.

Ultimately, providing fewer instances that require the need for an IB Type Elevator to be sent to a repair facility.

FEA Analysis Results

Results from FEAs (Finite Element Analysis), conducted by Keystone, confirm how the use of insert bushings can minimize the wear on the elevator (bores), and hinge and latch pins. Below are the exploded views of the hinge and latch areas where the applied stresses are reduced by 25% to 38% when using an IB elevator in place of a traditional elevator.

Keystone’s Drilling Elevators

Keystone Energy Tools is a leading manufacturer of Drill Pipe Elevators. We design and precision-machine all of our elevators to meet and exceed API Standards, with KET and the API monogram stamped on our equipment, you can be sure you are getting high-grade equipment at a competitive price, made in the USA.

Related Articles

Top 10 Trends Shaping the Oil and Gas Industry - Let's explore 10 of these trends that are transforming the outlook of the oil and gas industry for 2021 and beyond.

The importance of equipment repairs and maintenance in the oil and gas industry - Repair and maintenance are essential to mitigate corrosion, increase safety, and reduce expenses long term.

Introducing the Keystone Slip Type Elevators - Keystone offers Y Series Slip Type Elevators. The Y Series Elevators are center latch, tubing elevators made to catch collar type or integral joint tubing.

About Keystone Energy Tools

Keystone Energy Tools is a manufacturer with over fifty years of combined experience in designing, manufacturing, and delivering high-quality oilfield tools, including elevators, slips, dies and inserts, tongs dies, safety clamps, stabbing guides, drill pipe float valves, baffle plates, float valve pullers, rotating mouseholes, and tong blocks.

Keystone Energy Tools is a manufacturer with over fifty years of combined experience in designing, manufacturing, and delivering high-quality oilfield tools, including elevators, slips, dies and inserts, tongs dies, safety clamps, stabbing guides, drill pipe float valves, baffle plates, float valve pullers, rotating mouseholes, and tong blocks.

By using the latest in 3D modeling for product design and by staying current with the rapid advances in manufacturing technology and quality-assurance standards, Keystone is able to manufacture and produce the most reliable products on the market today. All Keystone Handling Tools are manufactured according to API 8C and API 7K Standards.