The American Petroleum Institute (API) Publications Programs and Services is a comprehensive resource for all API standards and practices, technical documents, and equipment specifications. The catalog also includes reports and studies regarding the safety, efficiency, and responsibilities of the petroleum industry. The latest catalog also features updated API Spec 8C standards.

- What is API 8C?

- What does API 8C apply for?

- API 8C Product Specification Levels

- API 8C Supplementary Requirements

What is API 8C?

API Specification 8C is a standard that provides requirements for the design, manufacture, and testing of hoisting equipment suitable for use in drilling and production operations.

What does API 8C apply for?

Specification 8C applies to drilling and production hoisting equipment. These specifications dictate industry standards for the engineering design, material, and testing process for drilling and production hoisting equipment. The standards in this section apply to the following pieces of equipment:

- Elevator Links

- Tubing and Drill Pipe Elevators

- Casing Elevators

- Square Shoulder Type A Elevators

- Spiders (if they can be used as elevators)

- Kelly Spinners (if they can be used as hoisting equipment)

- Sucker Rod Elevators

- Hoisting Sheaves

- Traveling Blocks and Hook Blocks

- Connectors and Link Adapters

- Rotary and Power Swivels

- Drill-string Motion Compensators

- Wire-Line Anchors

- Drilling Hooks

- Power Subs

- Pressure Vessels and Piping (if mounted on hoisting equipment)

- Safety Clamps (if used as hoisting equipment)

- Guide Dollies for Traveling Equipment

API 8C Product Specification Levels

API Specification 8C standard establishes two product specification level (PSL) requirements, PSL 1 and PSL 2. These PSL designations serve to define separate levels of technical requirements for parts.

All requirements set forth are applicable only to PSL 1 unless they are identified as being PSL 2. Requirements for PSL 2 include all standards for PSL 1 as well as additional practices outlined for PSL 2. Additional and supplementary requirements are only required where specifically stated.

API 8C Supplementary Requirements

API Spec 8C standard also defines the different supplementary requirements that may be agreed upon between purchasers and equipment manufacturers, including:

- SR 1: Proof load testing

- SR 2: Low-temperature testing

- SR 3: Data book

- SR 4: Additional volumetric examination of castings

- SR 5: Volumetric examination of wrought material

Keystone Energy Tools Knows API Standards Matter

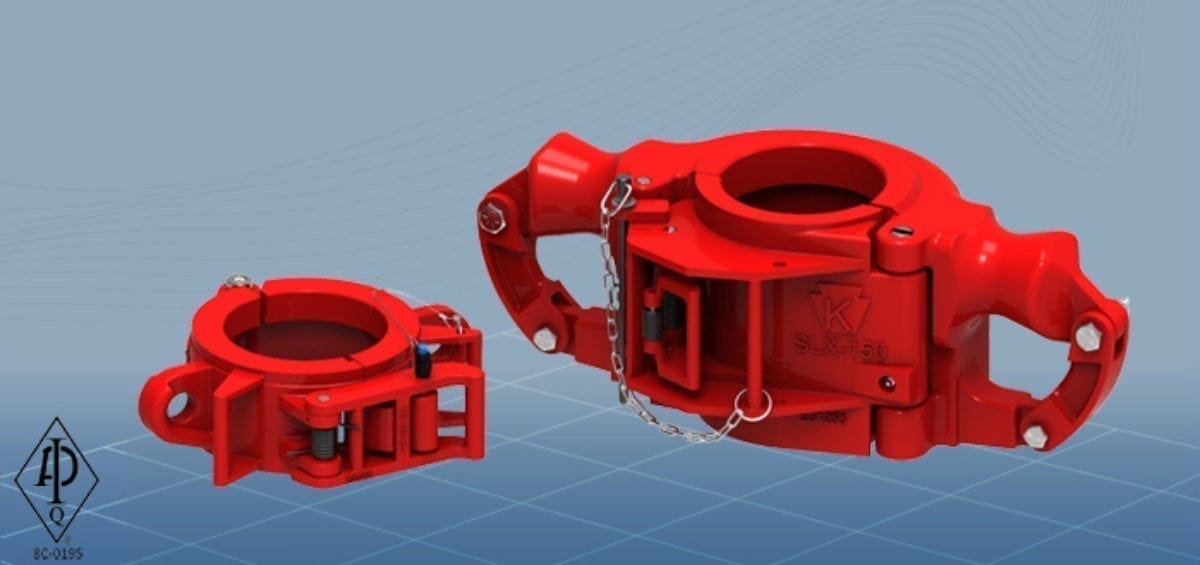

These standards ensure industry-wide uniformity and adherence to best safety practices. When it’s time to re-certify your elevator, an inspector will require that all applicable components are in compliance with the current 8C standards. The easiest way to ensure that your drillpipe elevator will make the grade is to buy exclusively from API-licensed manufacturers.

Keystone Energy Tools can help you understand industry specifications and ensure that your equipment meets or exceeds those standards. Knowledgeable staff work to get you the parts you need on time and for a good value. Keystone only works with products that are API compliant and of the highest quality. For a quick quote or answers to your questions, contact Keystone any time.

All Keystone Handling Tools are manufactured according to API 8C & API 7K Standards, and compliant with ABS CDS.

About Keystone Energy Tools

Keystone Energy Tools is a manufacturer with over fifty years of combined experience in designing, manufacturing, and delivering high-quality oilfield tools, including elevators, slips, dies and inserts, tongs dies, safety clamps, stabbing guides, drill pipe float valves, baffle plates, float valve pullers, rotating mouseholes, and tong blocks.

Keystone Energy Tools is a manufacturer with over fifty years of combined experience in designing, manufacturing, and delivering high-quality oilfield tools, including elevators, slips, dies and inserts, tongs dies, safety clamps, stabbing guides, drill pipe float valves, baffle plates, float valve pullers, rotating mouseholes, and tong blocks.

By using the latest in 3D modeling for product design and by staying current with the rapid advances in manufacturing technology and quality-assurance standards, Keystone is able to manufacture and produce the most reliable products on the market today. All Keystone Handling Tools are manufactured according to API 8C and API 7K Standards.