With so many different types of drilling elevators, and the care that it takes to maintain them for safety and operational purposes, we wanted to take a moment to fill you in on everything that we know that you should be thinking about when it comes to them. This article in particular will cover Square Shoulder Type A Series elevators.

About Square Shoulder Type A Elevators

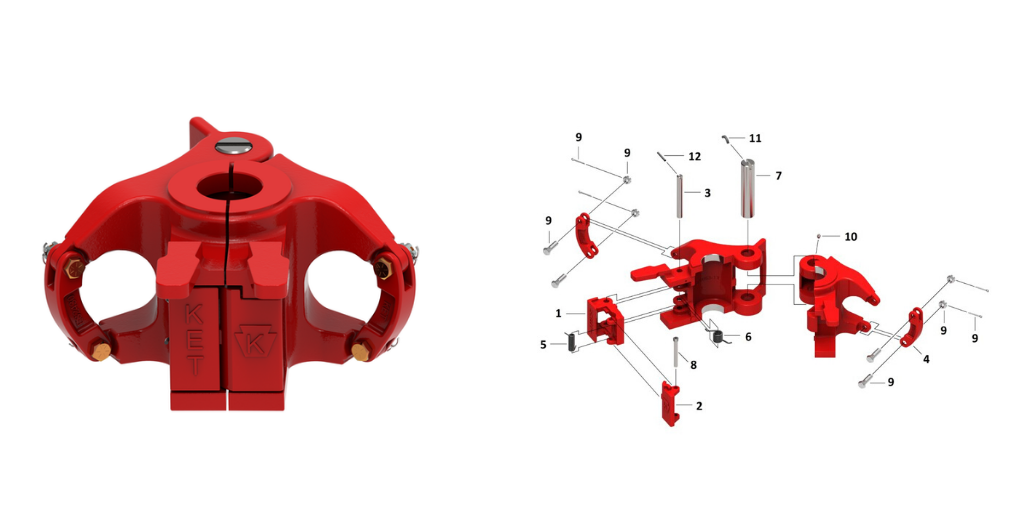

Square shoulder, “A" type elevators, are used for handling casing, tubing, and collar-type drill pipe. They are composed of two halves, each part generally weighing the same amount.

This provides proper balance and makes the equipment easier to open and close. They also have a latch, safety latch lock combinations, and operating handles to assist with managing operations and operator safety.

API Certified Equipment

To ensure that you are receiving a quality elevator it is highly recommended that you only buy API certified equipment. The American Petroleum Institute (API) licenses “Drilling and Production Hoisting Equipment” manufacturers under API Spec 8C, which covers elevator links, tubing and drill pipe elevators, sucker rod elevators, spiders (if capable of being used as elevators) and various other types of handling tools.

API is a globally recognized certification and licensing leader in various industries, and also has extensive experience licensing and certifying regular elevators as well. Any manufacturer with the API seal of approval is compliant with API standards and has the proven capability to manufacture to API Product Specification Requirements.

Purchasing equipment from a supplier with API Certification ensures you are buying quality equipment that meets API industry standards.

Routine Inspection Of Square Shoulder Type A Elevators

Of all the tools on a drilling rig, elevators are one of the most stressed pieces of equipment. Due to this, they require regular inspection. KET's operation manual lays out the necessary inspections that must be performed for optimum performance.

There are 2 types of inspections the MRA and TMA Operating manual advise--daily inspections and inspections every 6 months.

Proper Elevator Inspection

- Visually inspects for cracks, loose fits or connections, and other signs of wear, corrosion or overloading.

- Check for loose or missing components, deterioration, proper lubrication, and adjustment.

- Check for worn hinge pin, latch pin and latch lock pin. These may inhibit proper closing of the door and latch lock engagement.

- Check for proper operation of Latch Stop mechanism. The Latch should not stop against the door when closed but have no more than ¼” of standoff from the door.

- Check springs for damage, deformation and lack of tension.

- Check link block bolts for nuts and cotter pins.

- Lubricate the elevator regularly during usage and storage to prevent corrosion. Use an extreme pressure, multi-purpose, lithium base grease of No. 1 or No. 2 consistency or a lubricant that meets MIL-SPEC-A907E.

**When greasing of pins make sure to pump grease until it comes out of both ends.**

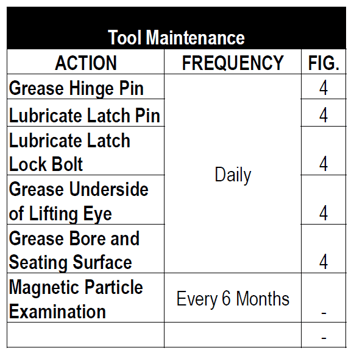

Periodic Actions/Examinations Chart

We recommend to maintain the elevator as prescribed below in the periodic Actions/Examinations chart.

6 Month Inspections

Every 6 months a full NDT (Non-Destructive Testing) inspection of all primary-load carrying components should be performed as defined by the manufacture, in addition to the daily checks specified above.

Replacement Parts

Only KET manufactured parts should be used on KET Elevators.

Upon noticing damaged parts, you should contact Keystone to talk with a sales rep. to discuss and order the proper parts.

It is important to remember that a simple routine visual inspection can end up saving your rig hundreds of thousands of dollars throughout its lifetime, and most importantly help you to keep your team safe.

Re-certification of Square Shoulder A Type Elevators

The purpose of re-certification is to verify and document that the equipment's condition and properties are congruent with API 8B Standards. The standards stipulate the acceptable tolerances of critical components, as well as the criteria for its proper performance.

Verification Process

The verification process documents the steps performed to re-certify the equipment. This documentation shows specific load tests performed and the results of these tests, ensuring your elevator performs according to API Standards.

Why Re-certify Your Elevator?

Re-certifying your elevator is necessary to guarantee it is operating correctly.

This ensures the continuity of your daily operations and employee safety, but it can also assist you in preventing legal prosecution in case of an accident.

Contact KET to see about re-certifying your elevator and to get their recommended re-certification timeline and the details regarding the process.

Keystone’s Square Shoulder A Type Elevators

Our A Series Square Shoulder Elevators, which are manufactured in the USA and are API certified, come in two types: “TMA” 100-ton, and “MRA” 175-ton and cover pipe sizes 2 3/8” – 5 1/2”.

TMA (100 Ton) Square Shoulder

| Part No | Range | Size of Links | Weight |

|---|---|---|---|

| E500063 | 2-3/8″-5″ | 1-3/4″-2-3/4″ | 132.00 |

MRA (175 Ton) Square Shoulder

| Part No | Range | Size of Links | Weight |

|---|---|---|---|

| E30158 | 2-7/8″ – 5-1/2″ | 1-3/4″-2-3/4″ | 210.00 |

Keystone’s Drilling Elevators

KET is a leading manufacturer of Drill Pipe Elevators. We design and precision-machine all of our elevators to meet and exceed API Standards, with KET and the API monogram stamped on our equipment, you can be sure you are getting high-grade equipment at a competitive price, made in the USA.

KET’s full elevator line includes

- Bottleneck Elevators

- Slip Type Elevators

- Slim Hole Slips For Slip Type Elevators

- Side Door Elevators

- Single Joint Elevators

About Keystone Energy Tools

Keystone Energy Tools is a manufacturer with over fifty years of combined experience in designing, manufacturing, and delivering high-quality oilfield tools, including elevators, slips, dies and inserts, tongs dies, safety clamps, stabbing guides, drill pipe float valves, baffle plates, float valve pullers, rotating mouseholes, and tong blocks.

Keystone Energy Tools is a manufacturer with over fifty years of combined experience in designing, manufacturing, and delivering high-quality oilfield tools, including elevators, slips, dies and inserts, tongs dies, safety clamps, stabbing guides, drill pipe float valves, baffle plates, float valve pullers, rotating mouseholes, and tong blocks.

By using the latest in 3D modeling for product design and by staying current with the rapid advances in manufacturing technology and quality-assurance standards, Keystone is able to manufacture and produce the most reliable products on the market today. All Keystone Handling Tools are manufactured according to API 8C and API 7K Standards.