Drill pipe elevators are used for lifting and handling drill pipe, tubing, casing, and drill collars in the drilling industry. Due to the rigorous nature of their use, they are required to be made within strict durability guidelines and are subject to quality inspections.

- What Is the Keystone Elevator Difference?

- Keystone Square Shoulder Elevators

- Keystone Bottleneck Elevators

- Keystone Single Joint Elevators

- Keystone Side Door Elevators

- Keystone Slim Hole Slip Type Elevators

- Keystone Slip Type Elevators

What Is the Keystone Elevator Difference?

At Keystone (KET), we understand the importance of making sure that our parts are built with quality, not only to keep your operations running smoothly, but your team safe too. Due to this, we are a leading manufacturer of Drill Pipe Elevators.

We design and precision-machine all of our elevators to meet and exceed all API Standards. With KET and the API monogram stamped on our equipment, you can be sure you are getting high-grade equipment at a competitive price, made in the USA!

Please see below our suite of elevators below.

Keystone Square Shoulder Elevators

Keystone A Series Square Shoulder Elevators are designed to handle collar type drill pipe, tubing, and casing.

What Are Keystone's Two Types of Square Shoulder Elevators?

They come in two types, “TMA” 100-ton, and “MRA” 175-ton and cover pipe sizes 2 3/8” – 5 1/2”.

TMA Square Shoulder Elevator (100 Ton)

| Part No | Range | Size of Links | Weight |

|---|---|---|---|

| E500063 | 2-3/8″-5″ | 1-3/4″-2-3/4″ | 132.00 |

MRA Square Shoulder Elevator (175 Ton)

| Part No | Range | Size of Links | Weight |

|---|---|---|---|

| E30158 | 2-7/8″ – 5-1/2″ | 1-3/4″-2-3/4″ | 210.00 |

Have questions about our Square Shoulder Elevators?

Keystone Bottleneck Elevators

Keystone G-Series Bottleneck Elevators are designed for drill pipe with an 18 deg. taper.

What Are Keystone's Five Types of Bottleneck Elevators?

They are available in five types, “MG” 100-ton, “RG” 150-ton, “MGG” 250-ton, and “GG” 350-ton, and “HGG” 500-ton.

They cover pipe sizes from 2 3/8” – 5 7/8”. The “MGG” and “GG” models can be fitted with a special wear bushing in the bottom to help reduce bore wear when used with Top Drive systems.

MG Bottleneck Elevator (100 Ton)

MG Bottleneck Elevator (100 Ton)| Part No | Range | Size of Links | Weight |

|---|---|---|---|

| E30157 | 2 3/8″ – 5″ | 1- 3/4″ – 2 -3/4″ | 240.00 |

RG Bottleneck Elevator (150 Ton)

| Part No | Range | Size of Links | Weight |

|---|---|---|---|

| E30155 | 2 3/8″ – 4 1/2″ | 1- 3/4″ – 2 -3/4″ | 350.00 |

MGG Bottleneck Elevator (250 Ton)

| Part No | Range | Size of Links | Weight | |

|---|---|---|---|---|

| E35005 | 3 1/2″ – 5 1/2″ | 2 1/4″ – 3 1/2″ | 600.00 | Add to Quote |

GG Bottleneck Elevator (350 Ton)

| Part No | Range | Size of Links | Weight |

|---|---|---|---|

| E31068 | 3 1/2″ – 6 5/8″ | 2 1/4″ – 3 1/2″ | 700.00 |

MGG IB Bottleneck Elevator (250 Ton)

| Part No | Range | Size of Links | Weight |

|---|---|---|---|

| E35005-IB | 2 7/8″ – 5″ | 2 1/4″ – 3 1/2″ | 600.00 |

| Part No | Range | Size of Links | Weight |

|---|---|---|---|

| E70013 | 4″-6-5/8″ | 2-1/4″-3-1/2″ | 1,220 |

GG IB Bottleneck Elevator (350 Ton)

| Part No | Range | Size of Links | Weight |

|---|---|---|---|

| E35005-IB (MGG) | 2-7/8″-5″ | 2-1/4″-3-1/2″ | 600.00 |

| E31068-IB (GG) | 2 7/8″ – 5″ | 2 1/4″ – 3 1/2″ | 750.00 |

| E31068-IB-2 (GG) | 2-7/8″-5 1/2″ | 2-1/4″-3-1/2″ | 800.00 |

Have questions about our Bottleneck Elevators?

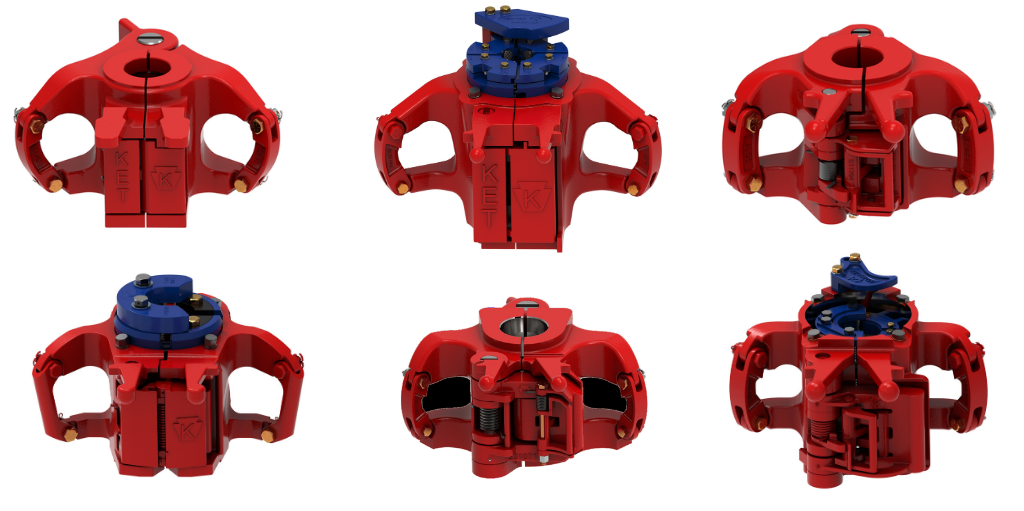

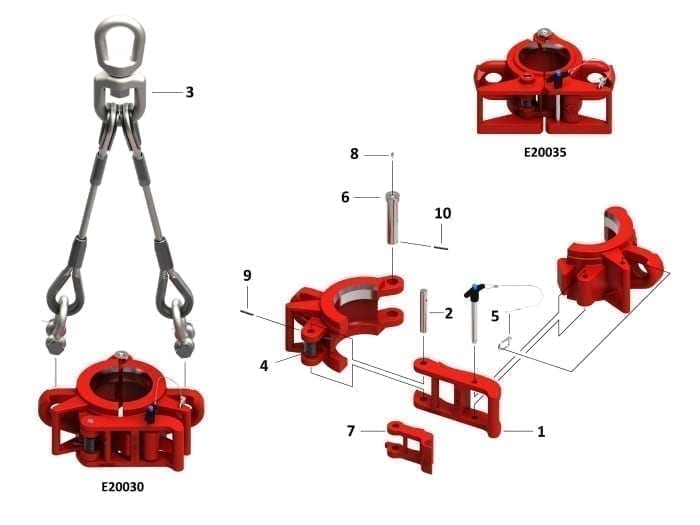

Keystone Single Joint Elevators

The Keystone “SJ” series single-joint elevator is rated for 7.5 tons. The elevator can be bored to accommodate 18 degree tapered drill-pipe or square-shoulder casing and tubing.

| Part No | Range | Weight |

|---|---|---|

| E20035 | 2 3/8″ – 4″ | 45.00 |

| E20030 | 4″ – 5 7/8″ | 67.00 |

| E20040 | 5 1/2″ – 8 5/8″ | 75.00 |

| E20050 | 9 5/8″ – 10 3/4″ | 93.00 |

| E20060 | 11 3/4″ – 14″ | 114.00 |

| E20065 | 16″ – 20″ | 130.00 |

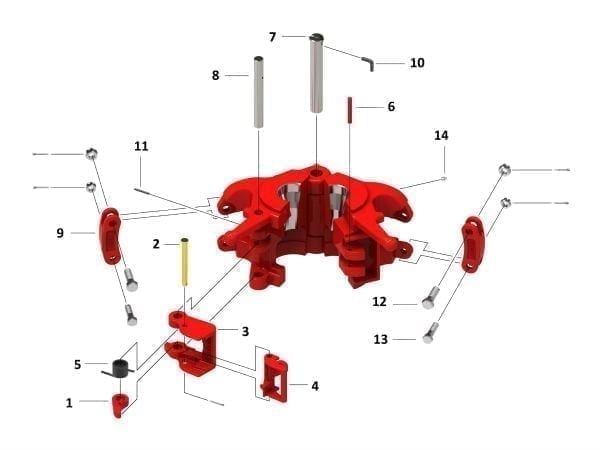

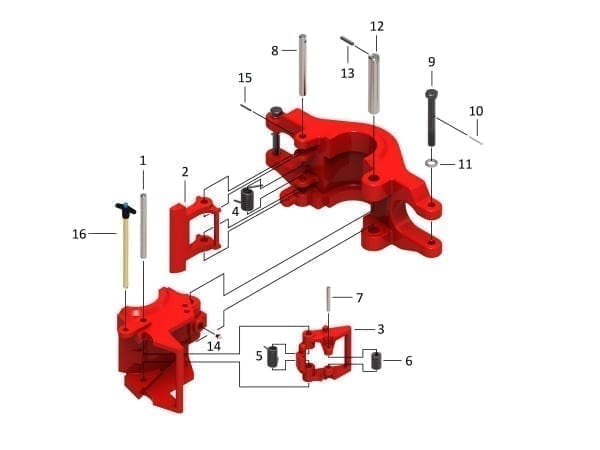

| Part# | Qty | Item | Description | Spares | Weight (lbs) |

|---|---|---|---|---|---|

| E20026-C | 1 | 1 | LATCH-E20030 | 6.00 | |

| E33035 | 1 | 2 | LATCH PIN-E20030 | 1 | .37 |

| E39-198 | 1 | 2 | LATCH PIN-E20035 | 1 | .37 |

| E34568 | 1 | 3 | SJ SWIVEL SUSPENSION ASSEMBLY | 1 | 29.00 |

| E39-034 | 1 | 4 | LATCH SPRING-E20030 | 2 | .20 |

| E7829-1 | 1 | 4 | LATCH SPRING-E20035 | 2 | .20 |

| E39-051-8 | 1 | 5 | LATCH LOCK RETAINER PIN | 1 | .35 |

| E39052 | 1 | 6 | HINGE PIN-BOTH | 1 | .10 |

| E39-190 | 1 | 7 | LATCH-E20035 | 4.00 | |

| E316-TI | 1 | 8 | TAP IN GREASE FITTING—BOTH | .10 | |

| E316RP | 1 | 9 | LATCH PIN RETAINER—BOTH | .10 | |

| P316RP | 1 | 10 | HINGE PIN RETAINER—BOTH | .10 |

Have questions about our Single Joint Elevators?

Keystone Side Door Elevators

Keystone SLX-Series are Side Door Elevators. These Casing Elevators are designed for casing and drill collar.

What Are Keystone's Four Types of Side Door Elevators?

hey are load rated at 65, 150, 250, and 350-tons and come in sizes from 3 ½” – 22 5/8”. The ears on the SLX 150, 250, and 350-ton are designed so the elevator can rotate freely in the bails when used for picking up or laying down pipe.

SLX- 65 Side Door Elevator

| Part No | Range | Weight |

|---|---|---|

| E38‐045 | 3 1/2” ‐ 5 1/2 | 160.00 |

| E38‐067 | 5 3/4” ‐ 8 5/8” | 190.00 |

| E38‐809 | “9” ‐ 10 3/4” | 218.00 |

| E38‐137 | “11” ‐ 14 1/4” | 275.00 |

SLX- 150 Side Door Elevator

| Part No | Range | Weight |

|---|---|---|

| E31239 | 5” ‐ 8 5/8” | 300.00 |

| E33950 | 9 5/8” ‐ 10 3/4” | 420.00 |

| E33982 | 11” ‐ 14 1/4” | 475.00 |

SLX- 250 Side Door Elevator

| Part No | Range | Weight |

|---|---|---|

| E31250 | 5 1/2” ‐ 8 5/8” | 350.00 |

| E33650 | 9 5/8” ‐ 10 3/4” | 470.00 |

| E33850 | 11” ‐ 14 1/4” | 525.00 |

SLX- 350 Side Door Elevator

| Part No | Range | Weight |

|---|---|---|

| E31275 | 5 1/2” ‐ 8 5/8” | 350.00 |

| E33675 | 9 5/8” ‐ 10 3/4” | 470.00 |

| E33875 | 11” ‐ 14 1/4” | 525.00 |

Have questions about our Side Door Elevators?

Keystone Slim Hole Slip Type Elevators

Keystone's Slim Hole Slip Type Elevator is your tool for small diameter slim hole drill pipe. Elevators are designed for small diameter slim hole pipe with capacities of 40, 75, or 150 Tons, the SHST is packed with 4 retractable inserts and 4 interlocking setting plates.The Slim Hole Slip Segments fit 2 3/8-2 7/8″ MYT, 2 3/8-3 1/2″ YT, and 2 3/8-3 1/2″ HYT Elevators.The latest Interlocking plate technology ensures the slip sets and bites evenly on the pipe as the retractable inserts engage the tube when closing the elevator.

Keystone Slip Type Elevators

Keystone offers Y Series Slip Type Elevators. The Y Series Elevators are center latch, tubing elevators made to catch collar type or integral joint tubing.

What Are Keystone's Different Types of Slip Type Elevators?

The models used for tubing are the LYT, MYT, YT, and HYT; and the YC, MYC, HYC, HYC-XR, and HYC-CL-XR for casing. They are load rated as the 20-ton LYT, the 40-ton MYT, 75-ton YT, and the 150-ton HYT covers tubular sizes from 3/4” – 3 1/2”. The 75-ton YC, the 100-ton YC-HD, the 125-ton MYC, and the 200-ton HYC covers a range of tubular sizes from 3 1/2” – 7 5/8”. The 200-ton and 250-ton HYC-XR covers a range of tubular sizes from 7 5/8” – 9 5/8”. The 300-ton and 350-ton HYC-CCL-XR covers a range of tubular sizes from 8 5/8″ – 10 3/4″.

All slip backs and die slots on Keystone slips are precision machined to ensure proper grip and to prevent bottlenecking or slip cuts to the pipe.

%20(1).png?width=310&height=155&name=Untitled%20design%20(18)%20(1).png)

KET LYT Slip Type Elevator (20 Ton)

| Part No | Range | Size of Links | Weight |

|---|---|---|---|

| E28750 | 3/4” – 2-1/16” | 1-1/4” – 2-3/4” | 58.00 |

MYT Slip Type Elevator (40 Ton)

| Part No | Range | Size of Links | Weight |

|---|---|---|---|

| E29328 | 3/4″ – 2 7/8″ | 1 1/4″ – 2 3/4″ | 148.00 |

YT Slip Type Elevator (75 Ton)

| Part No | Range | Size of Links | Weight |

|---|---|---|---|

| E23105 | 1.315″ – 3 1/2″ | 2 1/4″ – 2 3/4″ | 355.00 |

HYT Slip Type Elevator (150 Ton)

| Part No | Description | Range | Size of Links | Weight |

|---|---|---|---|---|

| E39284 | HYT Elevator Complete L/Slips | 2 3/8″ – 3 1/2″ | 2 1/4″ - 3 1/2″ | 740.00 |

HYT-HSS Slip Type Elevator (150 Ton)

| Part No | Description | Range | Size of Links | Weight |

|---|---|---|---|---|

| E39284 | HYT Elevator Complete L/Slips | 2 3/8″ – 3 1/2″ | 2 1/4″ - 3 1/2″ | 593.00 |

HYC Slip Type Elevator (200 Ton)

| Part No | Description | Range | Size of Links | Weight |

|---|---|---|---|---|

| E55310 | HYC Elevator Complete L/Slips | 3 1/2" - 7 5/8" | 2 1/4″ - 3 1/2″ | 1300.00 |

HYC-XR Slip Type Elevator (200 Ton)

| Part No | Range | Size of Links | Weight |

|---|---|---|---|

| E55310-XR | 7 5/8" - 9 5/8" | 2 1/4″ - 3 1/2″ | 1200.00 |

HYC-CL-XR Slip Type Elevator (250 Ton)

| Part No | Range | Size of Links | Weight |

|---|---|---|---|

| E55410 | 7 5/8" - 9 5/8" | 2 1/4″ - 3 1/2″ | 1200.00 |

HYC-CC-XR Slip Type Elevator (300 Ton)

| Part No | Range | Size of Links | Weight |

|---|---|---|---|

| E55510 | 8 5/8" - 10 3/4" | 2 1/4″ - 3 1/2″ | 1218.00 |

HYC-CCL-XR Slip Type Elevator (350 Ton)

| Part No | Range | Size of Links | Weight |

|---|---|---|---|

| E55610 | 8 5/8" - 10 3/4" | 2 1/4″ - 3 1/2″ | 1200.00 |

MYC Slip Type Elevator (200 Ton)

| Part No | Range | Size of Links | Weight |

|---|---|---|---|

| E200360 | 3 1/2" - 7" | 2 1/4″ - 2 3/4″ | 750.00 |

YC Slip Type Elevator (75 Ton)

| Part No | Range | Size of Links | Weight |

|---|---|---|---|

| E24140 | 3 1/2" - 7" | 2 1/4″ - 2 3/4″ | 380.00 |

Have questions about our Slip Type Elevators?

Why Choose Keystone Drill Pipe Elevators for Your Operation?

From square shoulder and bottleneck designs to slip type, side door, and slim hole configurations, Keystone’s drill pipe elevators are built to meet the demands of real-world drilling operations where safety, reliability, and uptime matter most. Every elevator is precision-machined, API-compliant, and manufactured in the USA to deliver consistent performance in the harshest environments.

When you choose Keystone Energy Tools, you’re investing in proven designs, rigorous quality standards, and a partner committed to keeping your operations moving safely and efficiently. Have questions or need help selecting the right elevator for your application? Our team is ready to help.

About Keystone Energy Tools

Keystone Energy Tools is a manufacturer with over fifty years of combined experience in designing, manufacturing, and delivering high-quality oilfield tools, including elevators, slips, dies and inserts, tongs dies, safety clamps, stabbing guides, drill pipe float valves, baffle plates, float valve pullers, rotating mouseholes, and tong blocks.

Keystone Energy Tools is a manufacturer with over fifty years of combined experience in designing, manufacturing, and delivering high-quality oilfield tools, including elevators, slips, dies and inserts, tongs dies, safety clamps, stabbing guides, drill pipe float valves, baffle plates, float valve pullers, rotating mouseholes, and tong blocks.

By using the latest in 3D modeling for product design and by staying current with the rapid advances in manufacturing technology and quality-assurance standards, Keystone is able to manufacture and produce the most reliable products on the market today. All Keystone Handling Tools are manufactured according to API 8C and API 7K Standards.

%20(1).png?width=500&height=250&name=Untitled%20design%20(18)%20(1).png)