At Keystone we understand the importance of making sure that our parts are built with quality, not only to keep your operations running smoothly, but your team safe too. Due to this, we are a leading manufacturer of high-quality oilfield tools.

Here is our new line of high-quality oilfield tools.

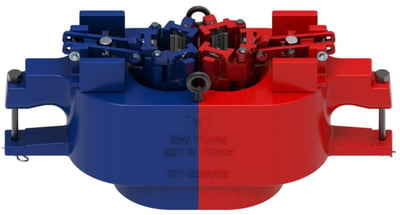

Dual Tool Elevator-Spider

The Keystone Dual Tool Elevator-Spider is build to provide the ability to run two strings of tubing at one time. The elevator-spider has the capability to operate one joint of tubing at a time. This tool abolishes the chances of bent tubing.

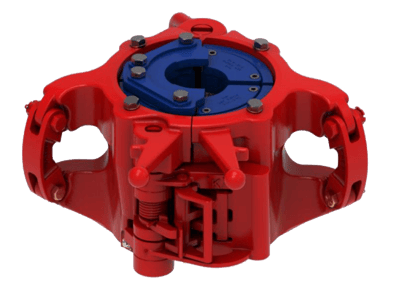

YC HD (100 Ton) Slip Type Elevator

Keystone offers Y Series Slip Type Elevators. The Y Series Elevators are center latch, tubing elevators made to catch collar type or integral joint tubing. They cover tubular sizes from “3/4” – 7”. All slip backs and die slots on Keystone slips are precision-machined to ensure proper grip and to prevent bottlenecking or slip cuts to the pipe.

Dual Flapper Check Valves

The Keystone Dual Flapper Check Valves are designed with cages, caps, and flappers manufactured from heat-treated 17-4 SS. These valves include Elgiloy springs, Viton elastomers and Teflon seats and with a working pressure of10,000 PSI.

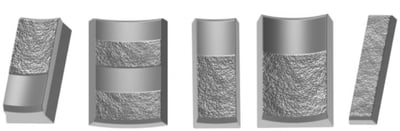

Key Grit Inserts

Keystone’s key grit inserts offer precision uniform plating with Tungsten Carbide. In addition, these inserts clench super and hyper chrome oxide coatings. KET inserts and dies are manufactured from quality materials and precision-machined to exacting tolerances.

Double Pin Single Joint Elevator

Keystone's elevators feature an ergonomic design allowing the unit to open from either hinge. With these elevators, the bail tilts will not obstruct the “derrick man” from being able to reach the hinge handle in the “monkey board”. In addition, a hinge pin rises up and turns, locking itself in the up position, which allows the elevator to open and close freely.

Double Latch Single Joint Elevator

Introducing the Keystone Double Latch Single Joint Elevator. These Elevators feature an ergonomic latch lock design. The latch lock mechanism latches around the door lug pin for confirmed closure. In addition, it includes a safety latch lock pin for added mitigation of potential dropped tubular.

Flapper Type Float Valves – 10,000 PSI and 15,000 PSI

The Model G-10 and G-15 are flapper type float valves that, when opened, offers an unobstructed bore through the float valve. The uniquely designed flapper closes rapidly to prevent shavings from entering the drill string when circulation stops and also assists primary BOP equipment in maintaining internal pressure control.

Flapper Type Float Valves - Model GS

The Model GS flapper-type float valve is designed for high flowing corrosive wells. Its unique flapper designed with a relief groove backed by a safe-guard pocket. In addition, the flapper protects the pin and spring from excessive wear. The Model GS flapper-type drill pipe float valve has an ID maximized to allow for the most flow possible while maintained its rated pressure.

Plunger Type Float Valves – 10,000 PSI and 15,000 PSI

The Model F-10 and F-15 are plunger-type float valves that provide a positive instantaneous shut-off, providing constant fluid control while drilling. Available with pressure monitoring and automatic fill.

The Keystone Energy Tools Difference

At Keystone (KET), we understand the importance of making sure that our parts are built with quality, not only to keep your operations running smoothly, but your team safe too. Due to this, we are a leading manufacturer of high-quality oilfield tools

We design and precision-machine all of our tools to meet and exceed all API Standards. With KET and the API monogram stamped on our equipment, you can be sure you are getting high-grade equipment at a competitive price, made in the USA.

Competitive Pricing

The critical requirements of the oil and gas industry include the need for high-quality parts at competitive prices. With Keystone, you get both — reliable products and great value.

On-Time Delivery

The demands of the oil and gas industry can be measured in hours, not days. That’s why you can always count on Keystone for reliable 24/7 service and dependable on-time delivery. Get same-day quotes and expedited shipping.

Ultimate Quality Delivery

Experience

Keystone has more than 50 years of combined experience in designing, engineering, manufacturing, and delivering high-quality oilfield tools and equipment.

Manufacturing

As your drilling rig supplier, we manufacture everything from handling tools to inserts and dies, and safety products to valves.

Quality Assurance

We are 100% committed to staying current with the rapid advances in manufacturing technology and quality-assurance standards.

3-D Modeling

We use the latest in 3D modeling to increase efficiency, streamline product creation, improve precision, and save money at the same time.

Keystone Energy Tools is a manufacturer with over fifty years of combined experience in designing, manufacturing, and delivering high-quality oilfield tools, including elevators, slips, dies and inserts, tongs dies, safety clamps, stabbing guides, drill pipe float valves, baffle plates, float valve pullers, rotating mouseholes, and tong blocks.

Keystone Energy Tools is a manufacturer with over fifty years of combined experience in designing, manufacturing, and delivering high-quality oilfield tools, including elevators, slips, dies and inserts, tongs dies, safety clamps, stabbing guides, drill pipe float valves, baffle plates, float valve pullers, rotating mouseholes, and tong blocks.

By using the latest in 3D modeling for product design and by staying current with the rapid advances in manufacturing technology and quality-assurance standards, Keystone is able to manufacture and produce the most reliable products on the market today.