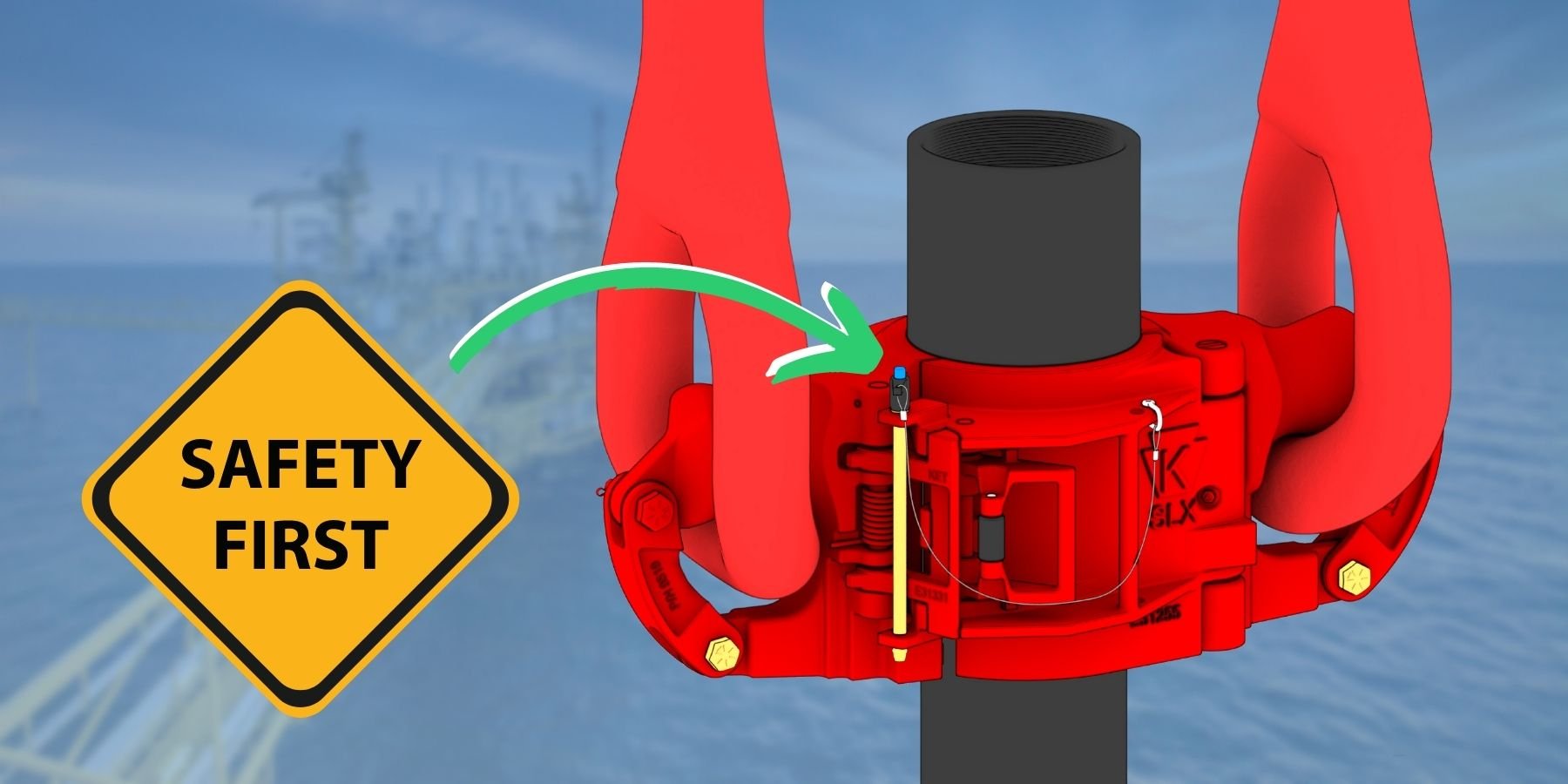

As the name suggests, SJ and SLX elevators are used to raise and lower different types of tubulars. They are an essential part of the drilling process, and their safety is of paramount importance. One of the key safety features of SJ and SLX elevators is the Safety Latch Lock Pins.

Here is everything you need to know about these Safety Latch Lock Pins.

- What are elevator safety latch lock pins?

- How do Single Joint and Side Door elevator's Safety Latch Lock Pins work?

- How can operators prevent injuries when using single joint & side door elevators?

What are elevator safety latch lock pins?

The Safety Latch Lock Pins are designed to keep the elevator's safety latch locked in place, preventing the elevator from being accidentally released. If the pins are not in place, or if they are not properly installed, the elevator latch could open and release a single joint or string of tubular's and cause serious injury or death.

In order to ensure the safety of your SJ and SLX elevators, it is important to regularly check the condition of the Safety Latch Lock Pins. If they are damaged or missing, they should be replaced or the elevator should be taken out of service immediately.

How do Single Joint and Side Door elevator's Safety Latch Lock Pins work?

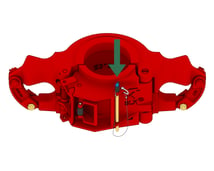

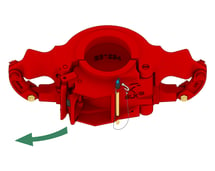

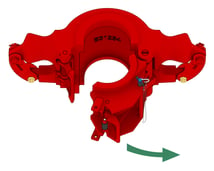

The operation of Keystone's elevators is straightforward. The elevator's door is opened by removing the Safety Latch Lock Pin and pulling outward on the Latch Lock. Next, operators shall install the Latch Lock Pin Retainer once the elevator is properly closed around the tubular.

How can operators prevent injuries when using single joint & side door elevators?

These elevators are a crucial part of the Wellbore construction process, and their safety should never be taken for granted. By regularly inspecting the condition of your elevator's Safety Latch Lock Pins, you can help to ensure that your elevator is always operating safely.

To prevent injury or elevator malfunction, operators shall inspect the elevator bore, latch, hinge pin, and latch pin regularly for wear. Failure to inspect these parts could cause injury or death.

In addition, operators shall not use the elevator if the latch (if any) or Safety Latch Lock Pins are malfunctioning. This can be done by securing the elevator's safety latch lock pin in its proper position. Latch or Safety Latch Lock Pin failure may result in injury or death.

Operators shall be competent, always read and follow the elevator's operating manual, in order to get familiar with how the elevator's Safety Latch Lock Pins work.

Keystone's Single Joint and SLX elevators

KET is a leading manufacturer of Drilling and Hoisting Equipment. We design and precision-machine all of our elevators to meet and exceed API Standards, you can be sure you are getting high-grade equipment at a competitive price, made in the USA.

We understand the critical requirements of the oil and gas industry and the need for high-quality tools and parts. For this reason, all of our elevators come equipped with Safety Latch Lock Pins to ensure safety.

The most important safety device for this tool is YOU. Your good judgment is the best protection against injury.

About Keystone Energy Tools

Keystone Energy Tools is a manufacturer with over fifty years of combined experience in designing, manufacturing, and delivering high-quality oilfield tools, including elevators, slips, dies and inserts, tongs dies, safety clamps, stabbing guides, drill pipe float valves, baffle plates, float valve pullers, rotating mouseholes, and tong blocks.

Keystone Energy Tools is a manufacturer with over fifty years of combined experience in designing, manufacturing, and delivering high-quality oilfield tools, including elevators, slips, dies and inserts, tongs dies, safety clamps, stabbing guides, drill pipe float valves, baffle plates, float valve pullers, rotating mouseholes, and tong blocks.

By using the latest in 3D modeling for product design and by staying current with the rapid advances in manufacturing technology and quality-assurance standards, Keystone is able to manufacture and produce the most reliable products on the market today. All Keystone Handling Tools are manufactured according to API 8C and API 7K Standards.