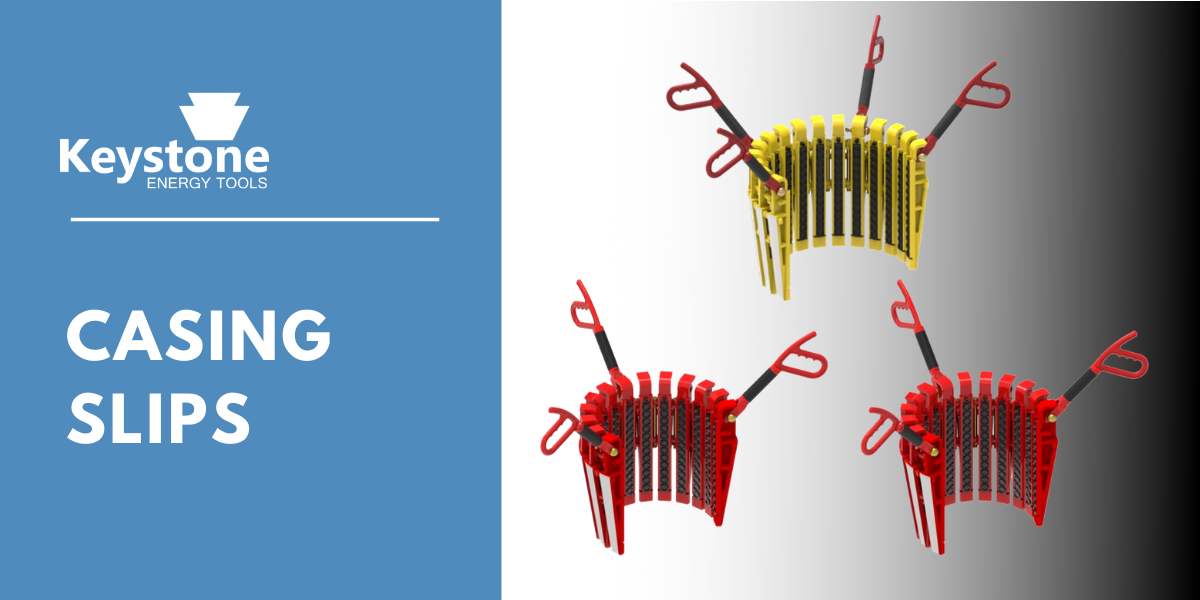

Keystone Energy Tools introduces its full line of casing slips designed to be used when running multiple types of casing.

Keep reading to see our full line of products and the specifics of each of Keystone Energy Tools' slips.

What are Casing Slips?

Casing is a large diameter pipe that is assembled and inserted into a recently drilled section of a borehole. Similar to the bones of a spine protecting the spinal cord, casing is set inside the drilled borehole to protect and support the wellstream. Casing Slips are tools used to help hold and run the pipe down the well.

Keystone's slip’s multi-segment-hinged design provides a full wrap-around to help prevent damage to the casing.

Which Types of Casing Slips Does Keystone Offer?

Keystone offers the following three types of Casing Slips:

- CMSXL

- CMS-3

- UC-3

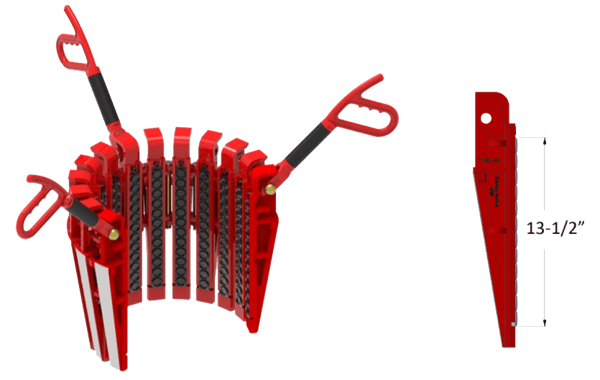

Type CMSXL Casing Slips

The KET “CMSXL” and “CMS-3” Casing Slips have a multi-segment design which gives a full wrap-around to help prevent damage to casing.

By adding or subtracting segments & inserts the slip can accommodate 6 5/8” - 30” O.D. casing.

The segments are made of alloy steel and are heat-treated for strength and wear resistance, then machined to strict quality controlled standards. CMS-XL slip has an API taper of 4”/ft on the diameter .

Type CMSXL Casing Slips Complete

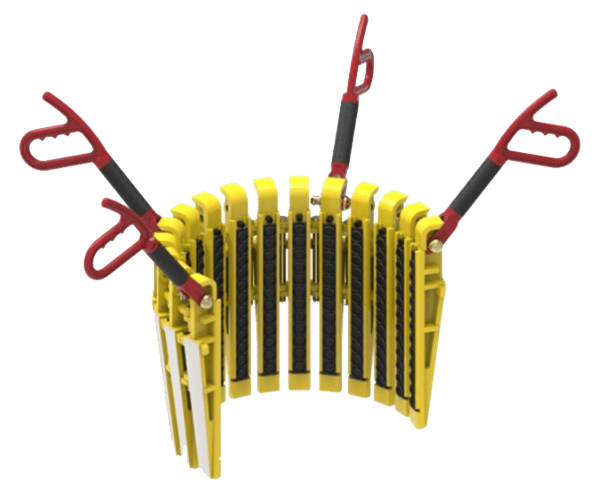

Type CMS-3 Casing Slips

The KET “CMSXL” and “CMS-3” Casing Slips have a multi-segment design which gives a full wrap-around to help prevent damage to casing.

By adding or subtracting segments & inserts the slip can accommodate 6 5/8” -30” O.D. casing. The segments are made of alloy steel and are heat-treated for strength and wear resistance, then machined to strict quality controlled standards.

CMS-3 slip has an API taper of 3”/ft on the diameter.

Type CMS-3 Casing Slips Complete

How Are Keystone's Casing Slips Made?

Our casing slips are manufactured from heat-treated alloy steel, increasing strength and resistance to wear.

Most of our slips have an API taper of 4″/ft. on the diameter, however, our CMS-3 has a 3″/ft. taper.

All slips are load rated and equipped with our safety flex handles.

Our slips are designed and precision-machined to meet and exceed API Standards, with the API monogram stamped on our equipment, you can be sure you are getting high-grade equipment at a competitive price, made in the USA.

Keystone's Full Line of Slips

KET is a leading provider of drill pipe slips for the oil and gas drilling Industry. These slips are standard equipment for running tubulars such as drill pipe, drill collar, and casing.

The slips are machined, by strict quality control procedures, for use in API standard bowls.

KET’s full line of slips includes

- Drill Pipe Rotary Slips

- Drill Collar Slips

- Casing Slips

Want to learn more about Keystone's Casing Slips or Replacement Parts?

About Keystone Energy Tools

Keystone Energy Tools is a manufacturer with over fifty years of combined experience in designing, manufacturing, and delivering high-quality oilfield tools, including elevators, slips, dies and inserts, tongs dies, safety clamps, stabbing guides, drill pipe float valves, baffle plates, float valve pullers, rotating mouseholes, and tong blocks.

By using the latest in 3D modeling for product design and by staying current with the rapid advances in manufacturing technology and quality-assurance standards, Keystone is able to manufacture and produce the most reliable products on the market today.