Keystone Energy offers a wide variety of different types of Slips for different oil and gas needs.

Yet, in this blog, we will drill down into everything you need to know about our Drill Collar Slips.

What Are Drill Collar Slips and What Are They Used For?

Drill Collar Slips are devices used to grip and hold drill collars, as well as wash pipe, to the drill floor on an oil rig. The slips are constructed as a collection of metal wedges, hinged together to form a circular shape around the tubular. On the inside surface, the slips have replaceable steel teeth that grip the pipe.

The outsides of the slips are tapered and meets a similar taper on the drill floor.

After the slips are placed around the tubular, it is lowered so that the teeth on the inside grip the pipe and the slips are pulled down. The wedges then holds the tubular by the compressive force.

After work is completed, the string is raised, thereby unlocking the gripping action. The slips are then lifted away.

What Types of Drill Collar Slips Does Keystone Energy Offer?

Keystone Energy offers the following Drill Collar Slips:

- Type A

- C-1

- DCS

All KET slips have an API taper of 4″/ft on the diameter, are load rated, and equipped with safety flex handles.

Our slips are designed and precision-machined to meet and exceed API Standards, with the API monogram stamped on our equipment, you can be sure you are getting high-grade equipment at a competitive price, made in the USA.

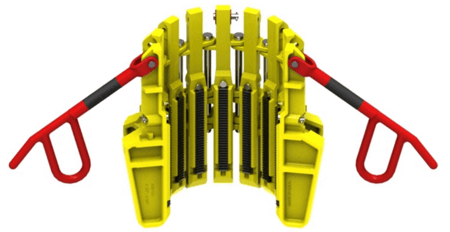

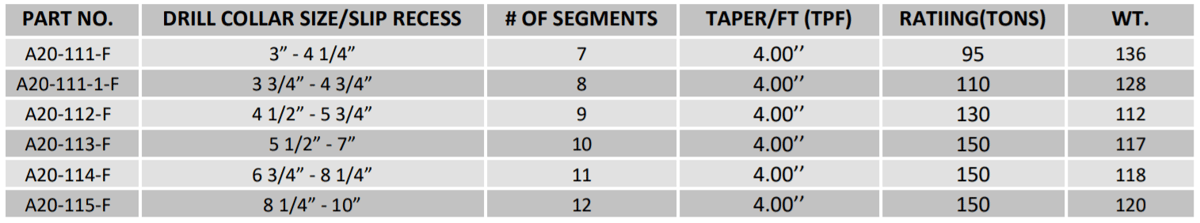

Type A Drill Collar Slips

The KET Type “A” Drill Collar Slip has a multi-segment design that allows it to hinge so that it fits all drill collars within the slip’s size range.

The slip segments are made of alloy steel which are heat-treated for strength and wear resistance. The slip is load rated and has an API taper of 4”/ft on the diameter.

All slip assemblies are supplied with safety flex handles..

Type A Drill Collar Slips Complete

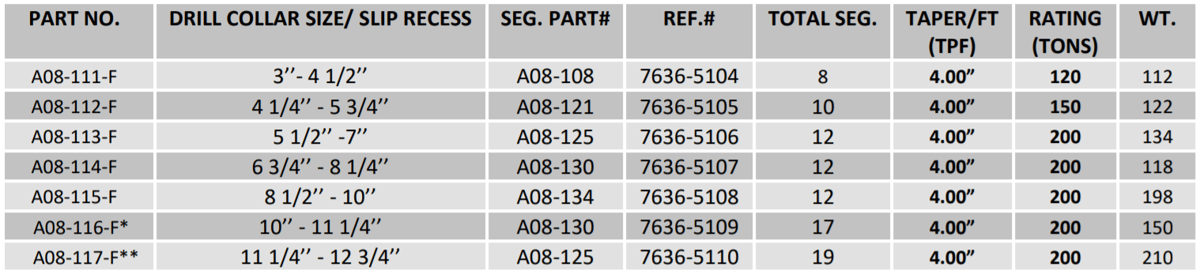

Type C-1 Drill Collar Slips

The KET “C-1” Drill Collar Slip has a multi-segment design that allows it to hinge so that it fits all drill collars within the slip’s size range.

The slip segments are made of alloy steel which are heat-treated for strength and wear resistance. The inserts are a continuous one piece design with approximately 7 1/2” of contact length.

The slip is load rated and has an API taper of 4”/ft on the diameter. For added safety, the KET “C-1” Drill Collar Slip is also provided with safety flex handles as a standard option

Type C-1 Drill Collar Slips Complete

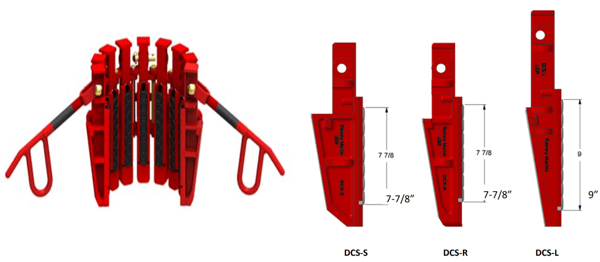

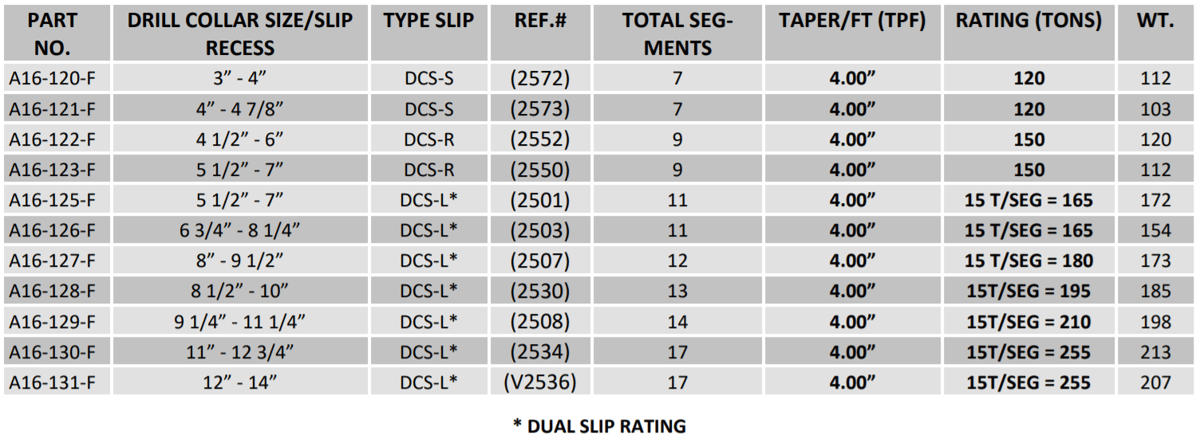

Type DCS Drill Collar Slips

The KET DCS Type Drill Collar Slip has a multi-segment design to give a full wrap-around to insure a proper slip setting.

The slips are made of alloy steel and heat-treated for strength and long life.

The slip is load rated and has an API taper of 4”/ft on the diameter. For added safety, the KET “DCS’’ Drill Collar Slip is also provided with safety flex handles as a standard option.

Type DCS Drill Collar Slips Complete

Keystone's Full Line of Slips

KET is a leading provider of drill pipe slips for the oil and gas drilling Industry. These slips are standard equipment for running tubulars such as drill pipe, drill collar, and casing.

The slips are machined, by strict quality control procedures, for use in API standard bowls

KET’s full line of slips includes

About Keystone Energy Tools

Keystone Energy Tools is a manufacturer with over fifty years of combined experience in designing, manufacturing, and delivering high-quality oilfield tools, including elevators, slips, dies and inserts, tongs dies, safety clamps, stabbing guides, drill pipe float valves, baffle plates, float valve pullers, rotating mouseholes, and tong blocks.

Keystone Energy Tools is a manufacturer with over fifty years of combined experience in designing, manufacturing, and delivering high-quality oilfield tools, including elevators, slips, dies and inserts, tongs dies, safety clamps, stabbing guides, drill pipe float valves, baffle plates, float valve pullers, rotating mouseholes, and tong blocks.

By using the latest in 3D modeling for product design and by staying current with the rapid advances in manufacturing technology and quality-assurance standards, Keystone is able to manufacture and produce the most reliable products on the market today. All Keystone Handling Tools are manufactured according to API 8C and API 7K Standards.